about us

The Future of Renewable Energy: Trickle Bio Power

Introducing Trickle Bio Power: Our team, fueled by a passion for sustainability, has joined forces to create a company dedicated to providing renewable energy solutions for commercial and industrial sectors. We’re here to make a positive impact on the environment while meeting your energy needs.

Our mission

To empower every person and every organization on the plant to achieve more ideas.

Our vision

To change the way we think about saving the companies.

Scope

we engrow working along with the production of biogas to electricity from a renewable fuel that’s produced from organic matter such as food and animal waste.

SERVICES

BIO GAS GENERATION

We specialize in producing biogas from a variety of organic wastes including poultry, cattle, tapioca, pig, sugarcane, and dairy waste. Our efficient process involves collecting, sorting, and preparing the waste materials before feeding them into anaerobic digesters. Through this process, we generate high-quality biogas consisting primarily of methane and carbon dioxide, which can be used as a renewable energy source.

We generate electricity from biogas, a renewable energy source derived from organic waste such as agricultural residues and animal manure. Through anaerobic digestion, we produce biogas, primarily methane, which powers generators or turbines to generate clean electricity. This sustainable process reduces greenhouse gas emissions and promotes efficient waste management while contributing to energy security.

PROJECTS

BIO GAS

Poultry waste:

Biogas from poultry waste offers a sustainable energy solution. By harnessing methane from poultry waste, we generate clean electricity while reducing environmental impact.

Cattle waste:

Utilizing biogas from cattle waste offers a renewable energy source. By capturing methane emissions, we produce clean electricity while mitigating environmental impact from agricultural operations

Cassava and Vegetables Waste

Biogas from cassava and vegetables waste presents an eco-friendly energy solution. By converting cassava and vegetables waste into biogas, we generate renewable energy while reducing waste and promoting sustainability.

Pig waste

Bio gas derived from pig waste is a sustainable energy source. By harnessing methane from pig waste, we produce clean electricity, reduce methane emissions, and promote environmental sustainability.

Sugarcane waste

Bio gas extracted from sugarcane waste is a renewable energy solution. By converting sugarcane waste into biogas, we generate sustainable electricity while reducing waste and supporting environmentally-friendly practices in the sugar industry.

Dairy waste

Bio gas from dairy waste offers a sustainable energy alternative. By capturing methane from dairy waste, we generate clean electricity, reduce methane emissions, and promote environmental stewardship within the dairy industry.

BIO GAS: FROM WASTE TO ELECTRICITY

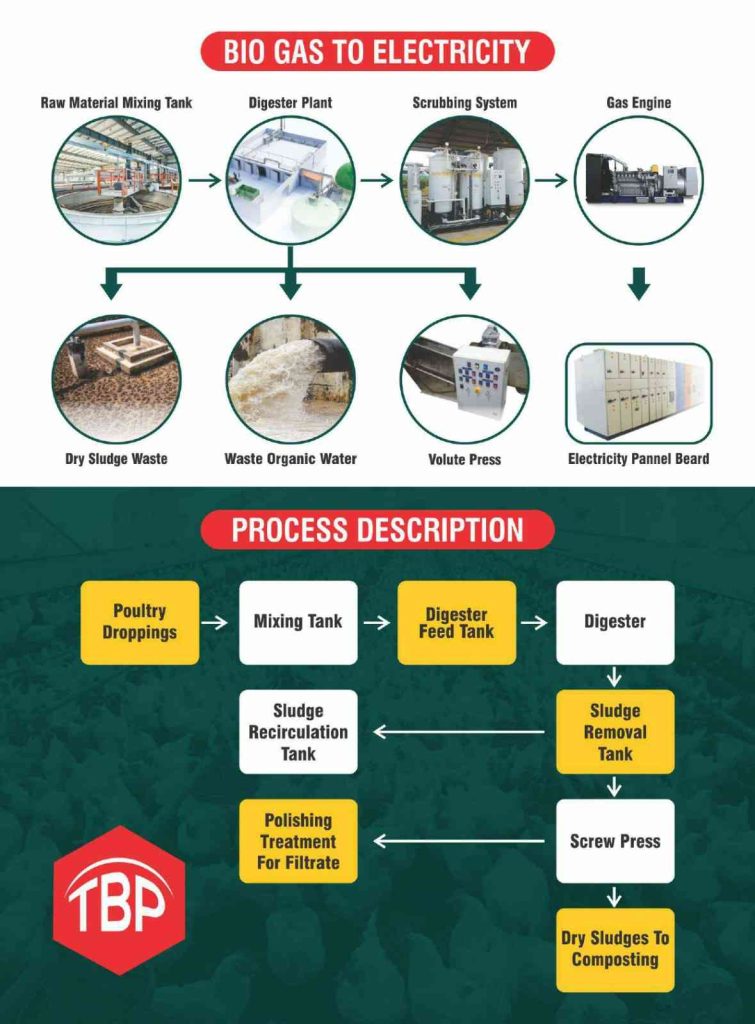

Biogas, a renewable fuel produced from organic matter, offers a sustainable way to generate electricity. Here’s detailed about breakdown of the process, step by step:

- Biogas Production:

Feedstock Selection: Choose organic materials like animal manure and food waste. Ensure proper sorting and pre-treatment to remove any contaminants.

Digestion: Load the feedstock into an airtight digester. Microorganisms in an oxygen-free environment (anaerobic digestion) break down the organic matter, releasing biogas.

Monitoring and Maintenance: Maintain optimal temperature and moisture levels inside the digester for efficient biogas production. Regularly remove digested material (digestate) which can be used as fertilizer.

- Biogas Processing:

Gas Cleaning: Biogas from the digester contains impurities like moisture and hydrogen sulfide. These need to be removed through filtration and scrubbing processes to ensure safe and efficient utilization.

Pressure Regulation: Biogas needs consistent pressure for optimal engine performance. Pressure regulators ensure a steady flow of gas to the next stage.

- Electricity Generation:

Biogas Engine: The cleaned and regulated biogas is fed into a specially designed internal combustion engine similar to those used in cars. The engine combusts the biogas, releasing heat energy.

Generator: The heat energy from the engine drives a connected generator. The generator converts this mechanical energy into electricity through the principle of electromagnetic induction.